Wogaard coolant saver kit

Coolant saver kit [Coolant saver]

Wogaard coolant saver technology

Save up to 50 percent of CNC machine coolant and reduce disposal costs with the Wogaard coolant saver kit. The coolant saver kit reclaims coolant from the swarf bin and returns it to the machine's main reservoir to be reused. The tool is easy to install and requires little maintenance. Stop throwing away used coolant and help the environment.

And remember: reduce, reuse, recycle.

The Wogaard coolant saver kit contains:

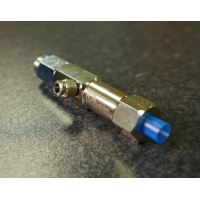

- Coolant saver unit

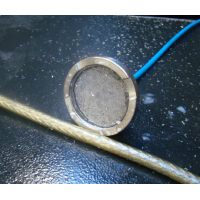

- Vacuum head

- Polyurethane hose: six-millimetre diameter and three-metres long (can be extended to 10 metres)

- 1.5-metre, 12-millimetre hose outlet

- T-fitting and straight-fitting kits

- Instruction manual

- One-year warranty

Contact Wogaard for full specifications and prices.

Benefits of the Wogaard coolant saver

1. Save up to 50 percent of your coolant:

- Save money and spend less time topping up coolant.

2. Improved swarf valve:

- You get a higher price for swarf without coolant.

3. Manpower reduction:

- No manual intervention to empty coolant from the swarf bin, as it is done automatically. Only swarf will require emptying from the bin.

4. Up to 90 percent saving in disposal:

- Save money through reduced coolant disposal costs.

5. Improved housekeeping:

- With no coolant in your waste bins, you stop coolant leaks and improve your workplace environment.

6. Help the environment:

- Recycle coolant and use the coolant saver kit without an external power supply.

On the road to ISO14001, with Wogaard's coolant saver kit you can reduce consumption of cutting fluid and water, reduce the amount of waste fluid collected and disposed of and end fluid leaks that create health and safety issues.

Testimonials: Mettis Aerospace

'Now we have the units fitted to the Matsuura machines in this cell we can look at calculating the savings that could be achieved by fitting the Coolant Saver to around 10 other machining centres we have identified as opportunities for improvement.'

As part of a continuous business improvement plan, Mettis Aerospace, a leading global service provider of precision-forged and machined components in titanium, aluminium and special steels, has installed the Wogaard coolant saver in a number of its advanced machining centres producing critical components.

Contact Wogaard to find out more.