High-quality strainer valves for any industry

Types of strainer valves [Strainer valves]

Omega valves supplies different types of strainer valves for various applications. Strainers can be installed permanently or temporarily for the commissioning phase of construction.

There are many types of strainer: duplex strainer, basket strainer, conical strainer, conical basket strainer, simple strainer, and Y strainer. Although the strainers are similar in operation they differ in design and can be customised for specific applications. Contact us now for more information.

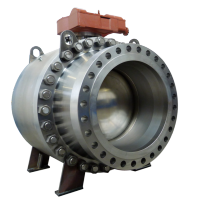

Strainer valves are generally used in pipelines to filter out solids from the flow of liquid or gas. They can be used in many different environments. Special materials are available on request for extreme temperatures, pressures and sizes of solids. This includes the screen, material of construction, and the soft parts, such as the seat and seal.

Features

| Feature | Benefit |

| Clean | The strainers can filter out fine solids to ensure clean outflow. |

| Strong | The valve can easily handle 6000 psi of pressure. It is strong and can accommodate high pressure. |

| High temperature | The strainers are well equipped to withstand high temperatures, including steam. |

| Minimise damage | Minimizes the damage to the pipelines, valves, pumps, flowmeters, and instrumentations. |

| Cost effective | Designed to minimise interruptions, wear and tear, and any associated costs. |

| Easy to maintain | Most strainer are easy to maintain and cause minimal interruptions. |

Types of strainer valves

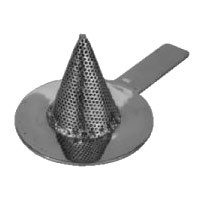

- Conical strainers – appropriate for commissioning equipment

- Y strainer – appropriate for general purposes

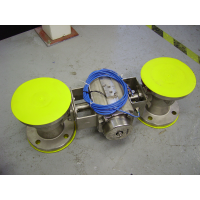

- Basket strainer – appropriate for regular, quick, and easy maintenance with minimal downtime

- Duplex strainer – appropriate for regular, quick, and easy maintenance with minimal downtim

Strainer valves can be installed in various locations including the following:

- Manufacturing plants

- Power stations

- HVAC

- Industrial factories

- Steam generation

- Boiler rooms

Omega Valves complies with the following standards:

- PED/97/23/EC

- ASME B16.5

- EN1092-1 (previously BS4504)

- ISO 9001:2008 - 0002582

The strainer valves can be manufactured to specific requirements

- Material – material of construction and soft parts, such as seat and seal

- Connection type – various connections options available for different strainers

- Size – various sizes available for different types of strainers

- Various ratings available

- Special testing available for Y strainers

- Different designs are available for the conical strainers

Contact us now for more details.