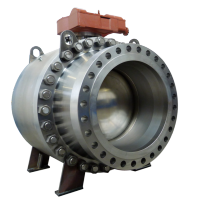

The stainless steel ball valve is ideal for all industrial applications

stainless steel ball valve [stainless steel ball valve]

Omega Valves has different types of stainless steel ball valve available to meet your requirements.

Ball valves are used for isolating or controlling the flow of fluids. The ball valve can be operated either manually by hand (locally) or automatically by an actuator (remotely). Most ball valve types are bi-directional and can be rotated in either direction.

Benefits of stainless steel ball valve

The stainless steel ball valve is the ideal option for industrial applications.

| Feature | Benefit |

| Corrosion resistance | Stainless steel is highly resistant to corrosion, stain, rust and environmental conditions. Stainless steel eliminates the need for a protective layer of coating or paint. |

| Extreme temperature | Stainless steel can withstand extreme temperatures ranging from -196⁰c to +425⁰c. |

| Clean |

Stainless steel is the preferred choice for cosmetic, pharmaceutical and food manufacturing industries. The material is highly resistant to corrosion and rusting, and supports the CIP (clean in process) procedure to prevent germ accumulations. Stainless steel hygienic ball valves are highly polished to avoid build-up of deposits on the metal surface, and are designed to avoid ‘dead areas’. |

| Versatile |

The 2 piece and 3 piece stainless steel ball valves are long lasting and easily maintainable. Spare parts for the valves are readily available and can be replaced easily to maintain a continuous work flow. These valves are versatile in nature and can be used in another section of the plant for different services. |

Stainless steel ball valves are ideal for the following industries

- Petrochemical

- Oil and gas

- HVAC

- Energy

- Food manufacturing

- Cosmetic

- Cleaning products manufacturing

Stainless steel ball valves are suitable for the following locations

- Houses

- Offices

- Hospitals

- Manufacturing factories

- Oil refineries and oil rigs

- Power stations

- Water treatment plants

- Gas work

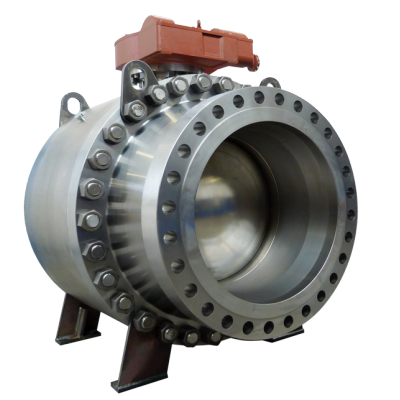

Standards and accreditation's fulfilled by Omega Valves

The AISI 300 series of stainless steels is the widely accepted standard in the industry. AISI 304 and AISI 316 are the two most popular grades of stainless steel offered by Omega Valves, which is certified to 3.1 international standards.

Standards

- Top flange: ISO 5211

- Flanges: ANSI B16.5

- Face to face (FTF): ANSI B16.10

- Testing: API 598, API 6D, BS6755-1

- Design: API 6D, B16.34

- Materials: NACE MR0175

Official approvals

- Certificate fire safe

- TA-LUFT

- ATEX 94-9EC

- API 6D

- PED 97/23/CE

- SIL 3 CAPABLE

- EN 161/EN 264

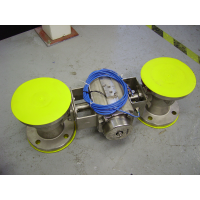

Omega Valves has the following types of stainless steel ball valve available

- 1 and 2 pieces screwed (BSP or NPT) floating ball valve

- 3 pieces screwed (BSP/NPT/socket weld/butt weld/tri-clamp) floating ball valve

- 2 piece flanged (ASA 150 or PN16/40) floating ball valve split body

- 3 pieces flanged trunnion mounted ball valve (ASA 150 to 2500)

- Wafer ball valve (ASA150 or PN16/40)

- 3 port ball valves (BSP or NPT screwed, flanged ASA 150 or PN16/40)

The following are the most common valve seat and seal materials used for stainless steel ball valve

- Virgin PTFE

- TFM™ 1600

- 15% glass filled PTFE

- 25% glass filled PTFE

- Carbon graphite filled TFM

- UHMWPE

- PCTFE

- Peek

- 50% stainless steel filled PTFE

- Flexible graphite