Butterfly valve types to suit any industrial application

butterfly valve [butterfly valve]

Omega Valves has different butterfly valve types available to meet your requirements.

Butterfly valves are used for isolating or controlling the flow of fluids. The butterfly valve can be operated either manually by hand (locally) or automatically by an actuator (remotely).

Butterfly valves are smaller and lighter than the ball, gate or globe valves. The simple construction and operating principles make the butterfly valves a cost-effective option. The valve can be modified to minimise fluid losses by altering the disk.

The soft-seated butterfly valve is designed to be cost-effective. With the soft-seated valve, only the disc, stem and seat touch the fluid, making it possible for the material of the body to be constructed of cheaper grade materials. Hence, many soft-seated butterfly valves are configurated in cast iron with stainless steel trim and EPDM seat.

The flow of fluids is controlled by the disc or damper, which rotates on a central stem. The butterfly valve rotates to 90⁰ or for a quarter turn to open or close the valve. Other specific applications are possible by opening the valve at fixed points of 10⁰, 20⁰, 40⁰ and 45⁰. Most butterfly valve types are bi-directional and can be rotated in either direction.

Butterfly valves are suitable for the following applications

- Most butterfly valve types are suitable for controlling the flow of air, powders and fluids.

- Special polytetrafluoroethylene (PTFE) lined butterfly valves are available for applications involving acids and aggressive chemicals.

- Metal Inconel or RPTFE seats with a carbon or stainless-steel body, is available on request for application in extreme temperatures and pressures.

Butterfly valves are used in the following locations

- Houses

- Offices

- Hospitals

- Manufacturing factories

- Oil refineries and oil rigs

- Power stations

- Water treatment plants

- Gas works

All butterfly valve types supplied by Omega Valves comply with the following standards

- ATEX

- BS OHSAS 18001

- DGRL

- DIN EN ISO 14001

- DIN EN ISO 9001

- DVGW

- EAC

- Fire Safe

- GOST (outbound)

- SIL

- TA Luft

- API 609 & API 598

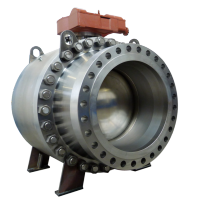

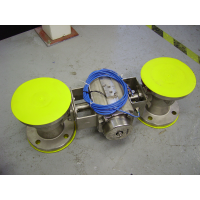

There are six butterfly valve types

- Wafer Butterfly Valve

- Lugged Butterfly Valve

- Double Flanged Butterfly Valve

- Concentric Butterfly Valve

- Double Offset Butterfly Valve

- Triple Offset Butterfly Valve

The butterfly valves are available in the following materials

- Cast iron

- Carbon steel

- Stainless steel

The seat for the butterfly valves are available in the following material and sizes

- EPDM – The seat is available from 2 inches to 24 inches.

- NBR, VITON, and PTFE – The seat is available from 2 inches to 12 inches.

- Metal or RPTFE seats (for the double offset and triple offset butterfly valve) – The size ranges from 2 inches to 24 inches.

Larger sizes are available on request. For engineered butterfly valves, get in touch with us now. We will be pleased to offer you a complete solution to fulfil your requirements.