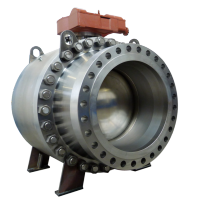

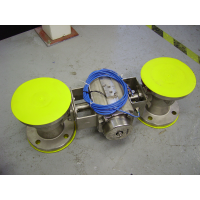

The stainless steel butterfly valve is ideal for all industrial applications

stainless steel butterfly valve [stainless steel butterfly valve]

Omega Valves has different types of stainless steel butterfly valve available to meet your requirements.

Butterfly valves are used for isolating or controlling the flow of fluids. The butterfly valve can be operated either manually by hand (locally) or automatically by an actuator (remotely). Most butterfly valve types are bi-directional and can be rotated in either direction.

Benefits of stainless steel butterfly valve

The stainless steel butterfly valve is the ideal option for industrial applications.

| Feature | Benefit |

| Corrosion resistance | Stainless steel is highly resistant to corrosion, stain, rust and environmental conditions. Stainless steel eliminates the need for a protective layer of coating or paint. |

| Extreme temperature | Stainless steel can withstand extreme temperatures ranging from -196⁰c to +425⁰c. |

| Clean |

Stainless steel is the preferred choice for cosmetic, pharmaceutical and food manufacturing industries. The material is highly resistant to corrosion and rusting, and supports the CIP (clean in process) procedure to prevent germ accumulations. Stainless steel hygienic butterfly valves are highly polished to avoid build-up of deposits on the metal surface, and are designed to avoid ‘dead areas’. |

| Versatile |

The 2 piece and 3 piece stainless steel butterfly valves are long lasting and easily maintainable. Spare parts for the valves are readily available and can be replaced effortlessly to maintain a continuous work flow. These valves are versatile in nature and can be used in another section of the plant for different services. |

| Weight | The high-performance butterfly valves are lighter and more compact in design, compared to the ball valves with the same pressure rating. |

Benefits of stainless steel double and triple offset butterfly valves

| Feature | Benefit |

| The ‘cam action’ and ‘right angled conical sealing’ design | The design ensures that the metal sealing components make contact. The result is an accurate sealing operation and a longer shelf life. |

| Low valve torque | Small actuators can be used, which lowers the cost of automation. |

| Minimal maintenance | Replaceable seat and seal components provide minimal maintenance. |

| Low fugitive emissions | Low fugitive emissions due to the quarter turn technology. |

| Metal to metal sealing | High pressure and temperature applications are possible with metal to metal sealing. |

Stainless steel butterfly valves are ideal for the following industries

- Petrochemical

- Oil and gas

- HVAC

- Energy

- Food manufacturing

- Cosmetic

- Cleaning products manufacturing

Standards and accreditation's fulfilled by Omega Valves

The AISI 300 series of stainless steels is the widely accepted standard in the industry.

Standards

- ATEX

- BS OHSAS 18001

- DGRL

- DIN EN ISO 14001

- DIN EN ISO 9001

- DVGW

- EAC

- Fire Safe

- GOST (outbound)

- SIL

- TA Luft

- API 609 & API 598

Omega Valves has the following types of stainless steel butterfly valve available

- Concentric wafer type butterfly valve

- Concentric lugged type butterfly valve

- Concentric double flanged butterfly valve

- Concentric wafer lined butterfly valve

- Concentric lugged lined butterfly valve

- High-performance double/triple offset wafer butterfly valve

- High-performance double/triple offset lugged butterfly valve

- High-performance double/triple offset double flanged butterfly valve

Seat materials used for stainless steel butterfly valve

| Seat | Temperature | Uses |

| EPDM | -30⁰c to +110⁰c | Air, water, ethyl alcohol, sugar industry, ammonium, weak acids hot water. |

| EPDM (HT) | -30⁰c to +145⁰c | Hot water steam. |

| Neoprene | -40⁰c to +95⁰c | Alkali acids, acids base. |

| Buna - N | -30⁰c to +90⁰c | Gasoline, diesel oil, vegetable oils, machine oils, natural gas, seat water, synthetic thinner. |

| Viton | -30⁰c to +205⁰c | Acid, detergent, water, steam, vegetable oils. |

| Silicon | -55⁰c to +175⁰c | Petroleum, hydroxides, alcohol, alkali. |

| PTFE | -40⁰c to +200⁰c | Acids, alcohol, ethyl oxide, ammonium, hexane, ether, benzene, hydrogen sulphide. |

| RPTFE | -40⁰c to +232⁰c | In higher temperatures with acids, alcohol, ethyl oxide, ammonium, hexane, ether, benzene, hydrogen sulphide, low pressure steam. |

| Stainless steel | -269⁰c to +649⁰c | Cryogenic and low temperature applications with liquid helium, liquid nitrogen, high temperature steam and hot oil. |