Compact butterfly wafer valve provides a low-cost valve solution

butterfly wafer valve [butterfly wafer valve]

Omega Valves has different butterfly wafer valves available to meet your requirements.

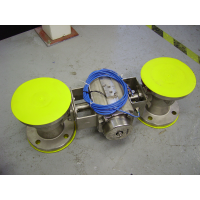

Butterfly wafer valves are used for isolating or controlling the flow of fluids. The butterfly valve can be operated either manually by hand (locally) or automatically by an actuator (remotely). Most butterfly wafer valve are bi-directional and can be installed in either direction, regardless of the flow.

Butterfly wafer valves are smaller and lighter than other butterfly, ball, gate or globe valves. The simple construction and operating principles make the butterfly wafer valves a cost-effective option.

Benefits of butterfly wafer valve

| Features | Benefits |

| Compact design | The valve has small dimensions and takes less space. The butterfly wafer valve is therefore ideal to use under tanks and other confined areas where large valves cannot fit. |

| Low weight | Butterfly wafer valves are light in weight. The valves are easy to install and require less manpower. The low weight of the butterfly wafer valve allows for it to be used on pipes with minimal support. |

| Low cost |

The disc, stem and seat are the only parts of the valve that come in contact with the substance. The body of the valve can therefore be constructed of an economical material. The overall cost and manufacturing time of the valve is minimised by the low-price material and the simple design of the butterfly wafer valve. |

| Multi-flange fitting | Butterfly wafer valves can be used on both American standard flanges (ANSI) and German standard flanges (PN16). |

| Uniformity of design | Most manufacturers of butterfly wafer valves follow similar measurements, enabling the valves to be replaced easily. The uniformity of design eliminates the need to alter or cut the pipework. |

Butterfly valves are suitable for the following applications

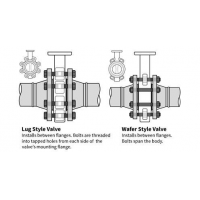

The butterfly wafer valve can only be used between flanges and not at the end of line, where there is only one flange.

- Most butterfly valve types are suitable for controlling the flow of air, powders and fluids.

- Special polytetrafluoroethylene (PTFE) lined butterfly valves are available for applications involving acids and aggressive chemicals.

- Metal Inconel or RPTFE seats with a carbon or stainless-steel body, is available on request for application in extreme temperatures and pressures.

Butterfly valves are not suitable for bulky or dry substances that can potentially wedge between the disc and seat and hinder the smooth operations.

Butterfly wafer valves are ideal for the following industries

- Water and effluent treatment factories

- HVAC

- Building services

- Refrigeration

- Oil and Gas

- Chemical industry

- Manufacturing

- Bulk handling

- Pharmaceutical

Butterfly wafer valves are used in the following locations

- Houses

- Offices

- Hospitals

- Manufacturing factories

- Oil refineries and oil rigs

- Power stations

- Water treatment plants

- Gas works

All butterfly wafer valves supplied by Omega Valves comply with the following standards

- ATEX

- BS OHSAS 18001

- DGRL

- DIN EN ISO 14001

- DIN EN ISO 9001

- DVGW

- EAC

- Fire Safe

- GOST (outbound)

- SIL

- TA Luft

- API 609 & API 598

Types of butterfly wafer valve

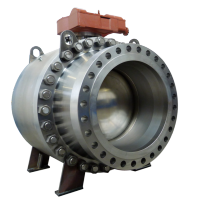

- Double flanged butterfly valve

- Concentric butterfly valve

- Double offset butterfly valve

- Triple offset butterfly valve

The butterfly wafer valves are available in the following materials

- Cast iron

- Carbon steel

- Stainless steel

Benefits of butterfly wafer valve

| Seat | Temperature | Uses |

| EPDM | -30⁰c to +110⁰c | Air, water, ethyl alcohol, sugar industry, ammonium, weak acids hot water. |

| EPDM (HT) | -30⁰c to +145⁰c | Hot water steam. |

| Neoprene | -40⁰c to +95⁰c | Alkali acids, acids base. |

| Buna - N | -30⁰c to +90⁰c | Gasoline, diesel oil, vegetable oils, machine oils, natural gas, seat water, synthetic thinner. |

| Viton | -30⁰c to +205⁰c | Acid, detergent, water, steam, vegetable oils. |

| Silicon | -55⁰c to +175⁰c | Petroleum, hydroxides, alcohol, alkali. |

| PTFE | -40⁰c to +200⁰c | Acids, alcohol, ethyl oxide, ammonium, hexane, ether, benzene, hydrogen sulphide. |

| RPTFE | -40⁰c to +232⁰c | In higher temperatures with acids, alcohol, ethyl oxide, ammonium, hexane, ether, benzene, hydrogen sulphide, low pressure steam. |

| Stainless steel | -269⁰c to +649⁰c |

Cryogenic and low temperature applications with liquid helium, liquid nitrogen, high temperature steam and hot oil. |

For more information, get in touch with us now. We will be pleased to offer you a complete solution.