Custom engineered valves for unique industrial requirements

engineered valves [engineered valves]

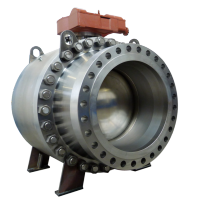

Engineered valves are a 100% customised solution for engineering, design or operational challenges.

Valves are manufactured to specific standards, which enables them to be used in a wide range of application. Engineered valves are a solution when standard valves are not suitable for carrying out specialised tasks.

Omega Valves has the required expertise and knowledge of valve applications to provide a specialised valve solution. Omega Valves carefully ascertains what the client requires and acquires the correct product from reliable manufactures.

Mini case study

Our clients from the oil and gas industry required an engineered valve.

Requirement

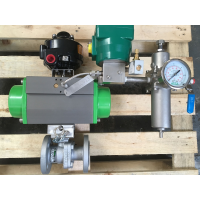

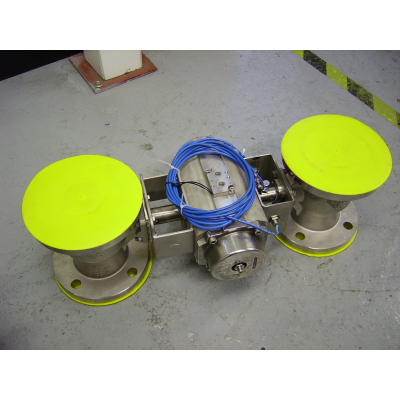

- Two actuated valves

- An open and close feedback

- ATEX rated for explosive environment

Challenge

- Limited space

- Offshore environment

Solution

- ‘Tandem linked arrangement’ to save space.

- Actuator to ATEX Eexd standard.

- The stainless steel pneumatic actuator operates both valves to conserve space.

- Special valve /actuator mounting bracket.

- ‘2 Off 2’ wire proximity sensors were built in the mounting kit assembly to achieve the open and close feedback.

- Stainless steel material and piping to prevent corrosion in Offshore environments.

Standards, documentation and testing

- The valve was tested with a 24VDC electrical signal and 4 bar air.

- The valve was tested to ensure the 45 second closing time and the robustness of assembly.

- The engineered valve was ATEX rated for use in Explosive environment. Required documentations were collated and supplied to the client on delivery.

Engineered valves are ideal in the following applications

- ATEX valve packages

- Abrasive or corrosive duties

- Extreme temperature or pressure

- Engineering problems

Engineered valves are ideal for the following locations

- Apartment building

- Office buildings

- Hospitals

- Manufacturing factories

- Oil refineries and oil rigs

- Power stations

- Water treatment factories

- Gas works

- Marine

- Offshore

Standards and documentations provided by Omega Valves

- Engineered valves require additional documentations, which a standard valve does not have.

- Bespoken testing of RT, MT, DP, PMI is available on order.