Pneumatic actuator to automate your industrial processes

pneumatic actuator [pneumatic actuator]

The pneumatic actuator is a cost-effective method for automating any industrial process, efficiently. The wide range of options, materials and configurations enable the valve to be controlled by a button and monitored in real time.

The pneumatic actuator eliminates the need for an operator to stand near the valves and operate them manually. The operator can now control the movement of the valve remotely, from the control room.

There are two types of pneumatic actuators based on its functionality. The linear actuator and rotary actuator. The linear actuator can actuate the linear valves and the rotary actuator actuates the rotary valves.

The pneumatic actuator can be mounted on the following valves

- Gate valve

- Globe valve

- Plug valve

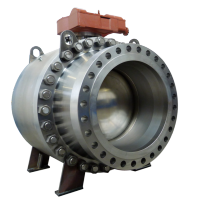

- Ball valve

- Butterfly valve

The following accessories enhance the functions of a pneumatic actuator

- The switch box informs the operator when the valve is open or closed.

- The electro-pneumatic positioner controls the valve using a 4-20mA signal.

- The Namur solenoid valve controls the air supply with an electrical signal.

- Quick exhaust valve

- Air filter regulator

- Throttle plate

- Needle valve

Main factors to consider when selecting a pneumatic actuator

- The substance

- Available instrument air

- The valve line pressure

- Temperature

- How often the valve will be operated

- Valve torque

- Environment

- Moisture level

The pneumatic actuator is ideal for the following locations and environments

- Apartment buildings

- Offices

- Hospitals

- Manufacturing factories

- Oil refineries and oil rigs

- Power stations

- Water treatment factories

- Gas works

- ATEX areas

- Offshore locations

Omega Valves has the following pneumatic actuators

- Actuated ball valve

- Actuated butterfly valve

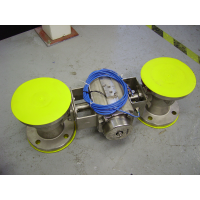

- Pneumatic actuator

- Rack and Pinion actuator

- Scotch Yoke actuator

- Ball valve actuator

- Butterfly valve actuator

- Stainless steel actuator

- ATEX actuator

- SIL 3 actuator

- PTFE coated actuator

- European manufacture actuator

- E.U manufacture actuator

- TU-CRE actuator

The pneumatic actuator complies with the following standards and regulations

- Quality System Management UNI EN ISO-9001:2008

- Authorization to Export Russian Federation, Belarus, Kazakhstan TU-CRE

- Declaration of E.S.H.R. Compliance Machinery Directive 2006/42/CE

- SIL-3 Safety Integrity Level IEC EN 61508/61511

- IP67 Protection Code Declaration EN 60529/A1:1999

- Declaration of Conformity for Using in Explosive Environments (aluminium) ATEX 2014/34/UE

- Declaration of Conformity for Using in Explosive Environments (stainless steel) ATEX 2014/34/UE

- Declaration of Conformity Design, Manufacture and Testing EN 15714-3:2009